What is Industry 5.0?

Industry 5.0 , the fifth industrial revolution also known as the ‘human touch’ revolution, is about the interaction between human and machines [1]. Industry 5.0 aims to transform machines, especially industrial robots from ‘tools to teammates’. A greater collaboration and interaction between the two is expected as the robots/machines will have sufficient capabilities and intelligence to work alongside humans. This will be driving the market trend to greater customization and personalization for mass produced goods in the future [2].

The current Industry 4.0 can be considered as a supercharged, connected and digitized automation, where advancing robotic capabilities and IIoT (Industrial Internet of Things) is the goal and a ‘lights-out’ 24 hr running factory the expected outcome. Unlike the Industry 4.0, in the future Industry 5.0 will focus on enhancing the human capabilities of reasoning, dexterity and creativity and add its value to the production process. It doesn’t mean that the industrial robots and the advances in automation and IIoT will not be crucial, on the contrary they will be a very critical component of Industry 5.0 . If Industry 4.0 was about robots and connectivity using IoT, Industry 5.0 will be about the human element. It will be about human-robot interaction and collaboration, that will help enable entirely new ideas and production methods in industry.

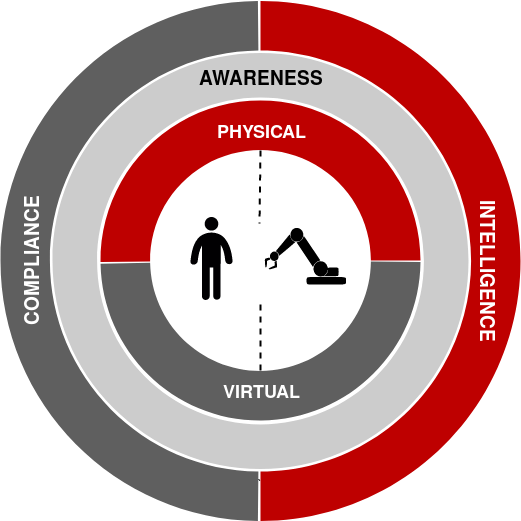

The challenges facing Industry 5.0 are human ‘Safety’, human’s ‘Trust in Automation’ and ‘Productivity’. As the human will be working in close proximity of robots, preventing any physical harm will be of utmost importance. ‘Trust in automation’ is about managing human expectations. As the robots and machines need to be intuitive and intelligent enough to help complement the human during the production process. The best way to build ‘Trust’ between and human and machine is through effective communication and making the robots compliant and interactive. Compliancy of a robot can be termed as the ease with which a human can transfer its knowledge and intention to the robot. ‘Productivity’ will be about enhancing the robot capabilities to maintain its speed, accuracy and robustness while ensuring efficient human-robot collaboration, so that the production throughput and quality is maintained [3].

For addressing the aforesaid challenges, the following technologies will play an important role. They are :

- Collaborative Robots

- Internet of Things (IoT) devices

- Artificial Intelligence

Collaborative Robots are made to work alongside humans for safe human robot interaction and possess the flexibility to perform various tasks. They are easy to use and teachable, allowing humans to transfer their visions in the production process. Some of the current functionalities are safety, hand guide motions, teaching with demonstration and easy reprogrammability.

Internet of Things – The machines and robots generate a lot of data, and with the help of sensors and IoT devices this data can be shared and made accessible. This is the goal of IIoT – Industrial Internet of Things. Some examples of the data generated and shared is commands/information between machines and robots and manufacturing process flow data. However, in Industry 5.0 with the focus of human interaction other IoT devices such as wearables for health monitoring and advanced communication between humans will also be critical. Some important applications and examples of IoT devices are listed below :

- Sensors on and in the machine telling about the data of the environment, the process and the health of the machines. IIoT can enable connectivity, accessibility and sharing of this data.

- With this data also comes the issue of data security – Cyber Security to prevent theft and manipulation will be very crucial.

- Wearables for Human Health monitoring. As humans are integral in Industry 5.0 , the data from wearable devices that provide biological signals, IoT capable smart glasses that provide information and communication to the user, augmented and mixed reality glasses such as Microsoft Hololens – for live assisting of users and overlaying information by merging the real and virtual world; these will all play an important role in IIoT aspect of Industry 5.0.

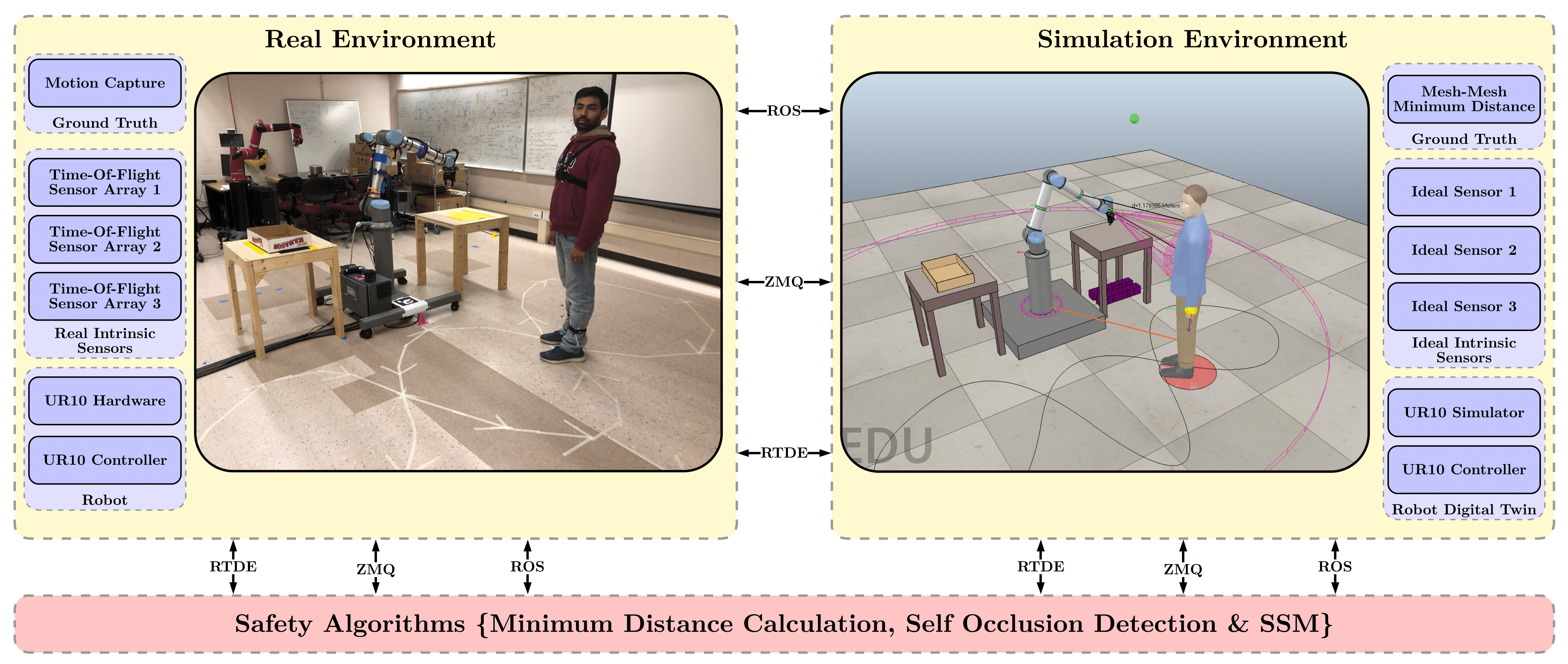

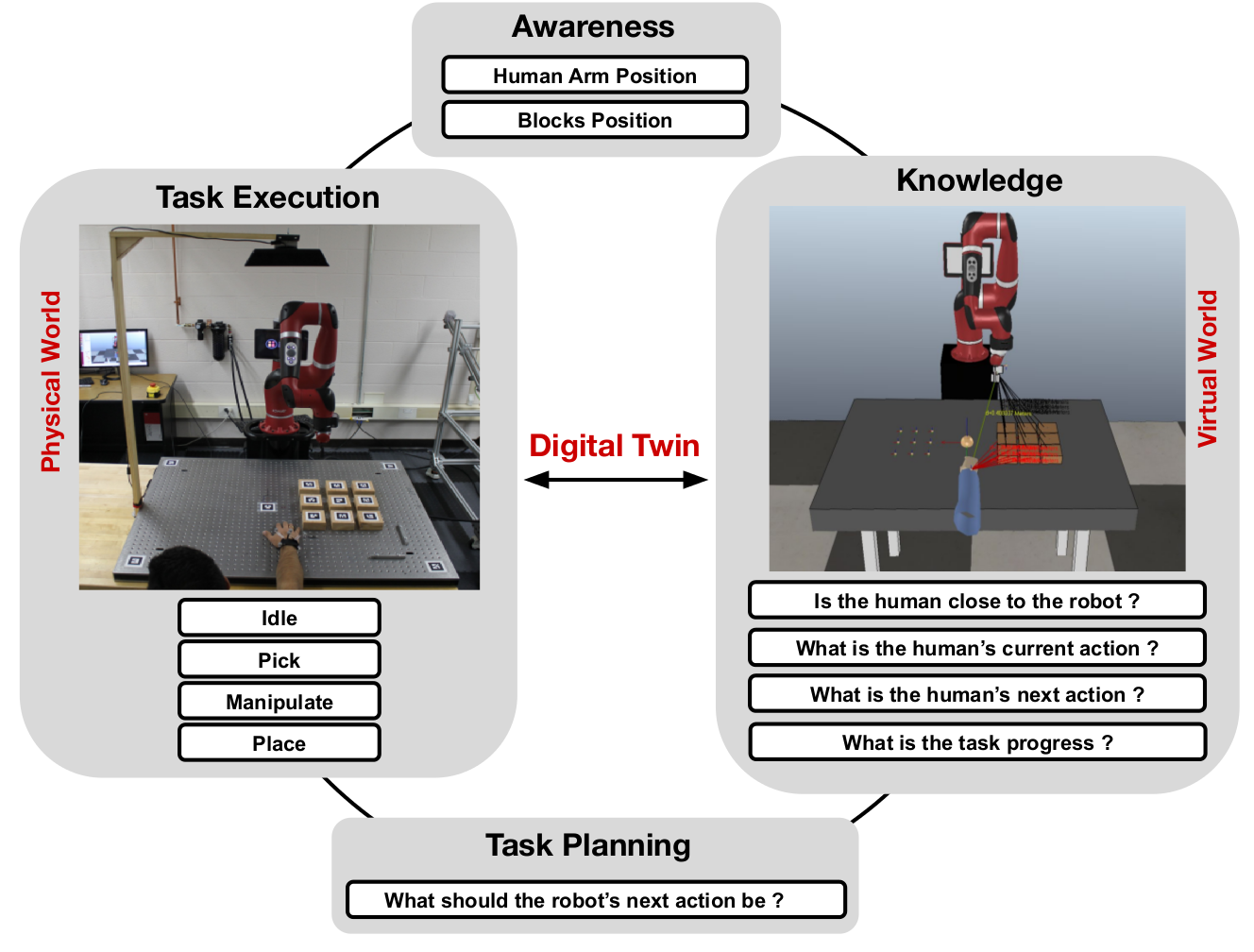

- Digitization and representation of the real world in the virtual simulated world , to allow humans to test production process and visualize ideas before implementation. This technology, that bridges the ‘real’ to ‘virtual’ is termed as the ‘Digital Twin’. This will be enabled by the data and information from the IIoT devices.

All these will require a connected and robust data communication, and IoT devices will play a very crucial role.

Artificial Intelligence:

The advances in Artificial Intelligence (AI) will be the most crucial in the Industry 5.0 setting. If the IIoT enables the communication and generation of data, AI will help make sense and help interpret the data enable efficient communication and human robot Interaction. A few research applications of using AI are listed below:

- Enhancing the sense of Awareness of the robot and its motion to make the human sharing its workspace feel safe.

- Conversational AI for better human-machine interaction. E.g. Google Virtual Assistant and the research done in the field of Natural Language Processing and Speech.

- Teaching robots from demonstration or other ways of knowledge transfer.

- Task Scheduling and Distribution between human and robot/machine

- Using human physiological signals and actions to determine human intention and build trust.

- Anticipating human actions and motions to better assist the human on the production process.

- Advanced perception and awareness of the robot using image and video processing.

- Optimizing the manufacturing process, fault prediction and diagnosis.

Thus, Industry 5.0 will enable the new form of production in industry where the human will be free to create and innovate without worrying about the limitations of production.

[1] Welcome to Industry 5.0, By Esben H. Østergaard, ISA Publication, In-Tech Magzine, PhD. https://www.isa.org/intech/20180403/

[2] What is Industry 5.0 and How Will Industrial Robots Play a Role? RIA https://www.robotics.org/blog-article.cfm/What-is-Industry-5-0-and-How-Will-Industrial-Robots-Play-a-Role/99

[3] S. Kumar and F. Sahin, "A framework for an adaptive human-robot collaboration approach through perception-based real-time adjustments of robot behavior in industry," 2017 12th System of Systems Engineering Conference (SoSE), Waikoloa, HI, 2017, pp. 1-6. doi: 10.1109/SYSOSE.2017.7994967

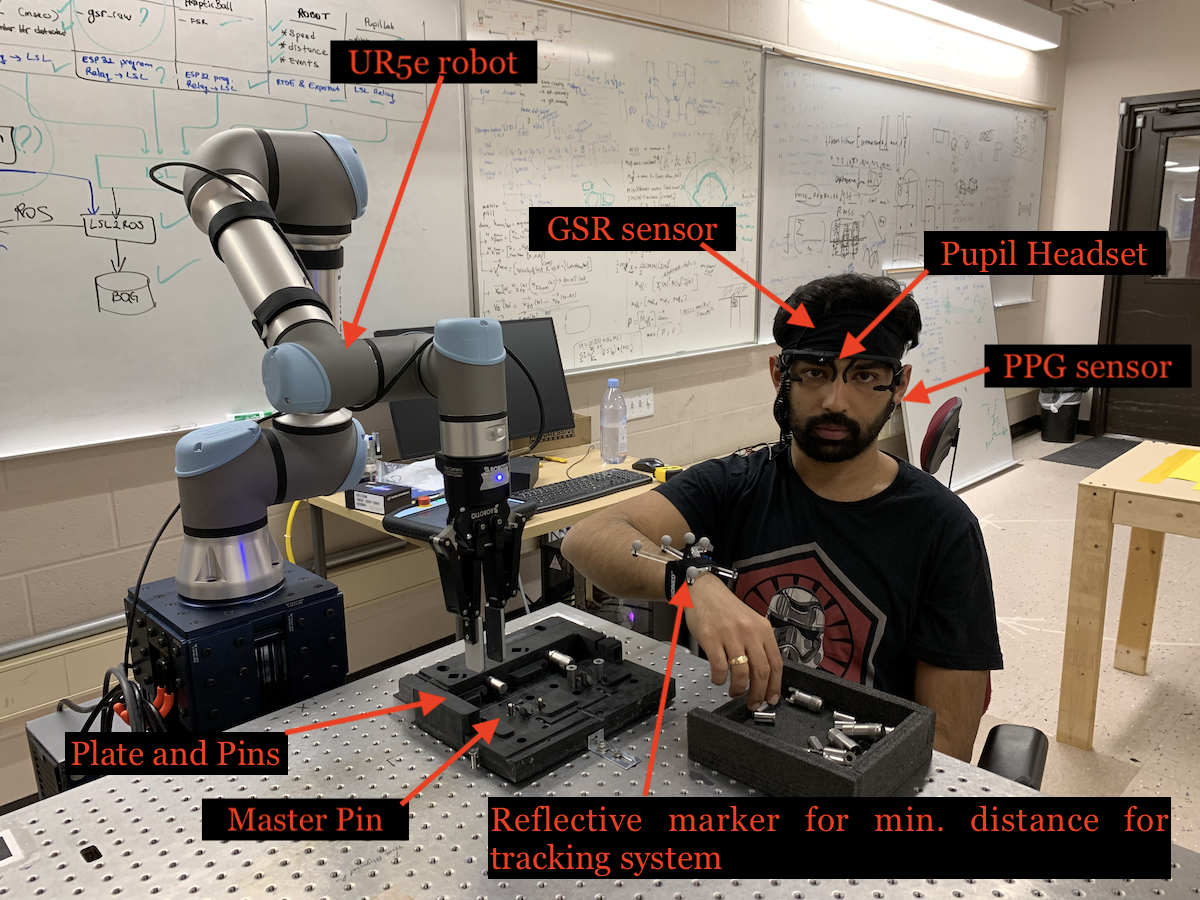

A TestBed Framework for Monitoring Human Physiological Response during Human Robot Collaborative Task

The objective of the experiment is to monitor effect of the acceleration and trajectory of the robot on human physiological signals during collaborative task. By concurrently monitoring robot and human state, we hope to quantify a human operator comfort level while working in a shared workspace that may be triggered by changes in robot motion. The experiment was performed using UR5e (Universal Robot) six degree of freedom (DoF) arm robot, as shown in Figure. The UR5e is a common collaborative robot with payload of 5 kg, which is suitable for manufacturing environment and laboratories.